Bridgnorth Aluminium

Two key construction phases as part of a broader programme to improve and expand aluminium production facilities

Andrew Scott Ltd successfully delivered two major construction phases for Bridgnorth Aluminium Ltd, forming part of a wider programme to enhance and expand the client's aluminium production capabilities. Both phases were delivered within a live, safety-critical environment, requiring close coordination with operational teams to minimise disruption to ongoing manufacturing processes.

Phase 1: Cast House Extension

The first project involved the design and construction of a new single-storey, steel-framed, metal-clad building, covering approximately 3,700 m². This extension accommodates a new melting furnace, holding furnace, and a slab casting facility, all supported by a stand-alone air filtration plant and chimney.

Key works included:

Excavation and removal of approximately 14,000 m³ of earth and rock to form deep foundations for heavy equipment.

Installation of drainage and all associated ancillary infrastructure.

Selective demolition of existing site structures to prepare for new construction.

Phase 2: Litho-2 Project – Rolling Mill, High Bay & Finishing Line

This complex phase included the construction of new foundations and internal infrastructure to support Bridgnorth’s advanced rolling and finishing operations, all within the confines of existing production buildings.

Rolling Mill – Building B14a

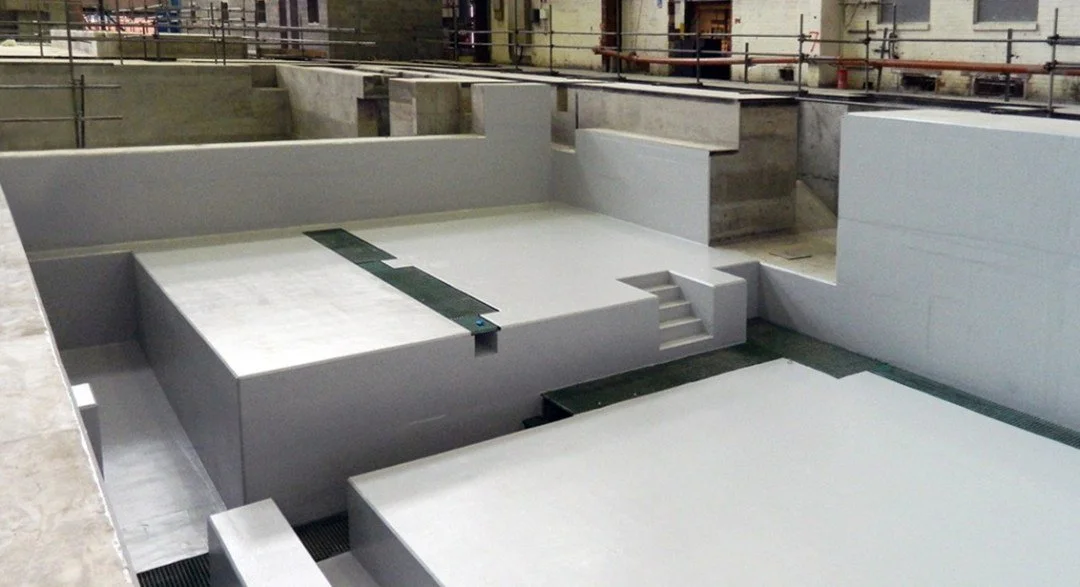

Construction of a new 20m wide x 45m long x 9m deep basement, incorporating suspended slabs, plinths, and corbels to support mill equipment.

Works were complicated by the presence of redundant heavy equipment foundations and adjacent existing basements.

High Bay Foundation

Excavation of a 3.5m deep trench along the full length of the western bay, immediately adjacent to external walls and structural column foundations.

Required precise sequencing and temporary works to protect adjacent structures.

Finishing Line

Construction of a raft of independent reinforced concrete machine foundations within Building B14a.

Creation of a connecting tunnel and associated access stairwells, linking the Finishing Line to the Cold Rolling Mill basement via a route beneath the High Bay structure.

Delivery of a new substation building a steel-framed, blockwork enclosure with a concrete roof and a raised access floor, constructed entirely within the existing building envelope

These works showcased Andrew Scott Ltd’s capability in delivering highly complex civil and structural engineering solutions in live industrial environments, where safety, precision, and coordination were critical to the success of the programme.